Tidying up the BMW R100RT

The single sided swinging arm had a few rust spots which I wanted to address and the easiest way was to strip the back end and remove the arm completely. Once that's done its not much of a job to pull the gearbox out to give access for further cleaning. Remember that this bike is now over 27 years old and nothing has been touched other than during routine servicing. This means that the clutch splines will be bone dry, the clutch lever arm will need looking at and those notorious gear change springs will be the originals. Motobins do a kit for the gear box which includes those upgraded springs, end cover gasket, new seals, circlips and a proper bearing for the cam-plate detent instead of the original nylon roller.

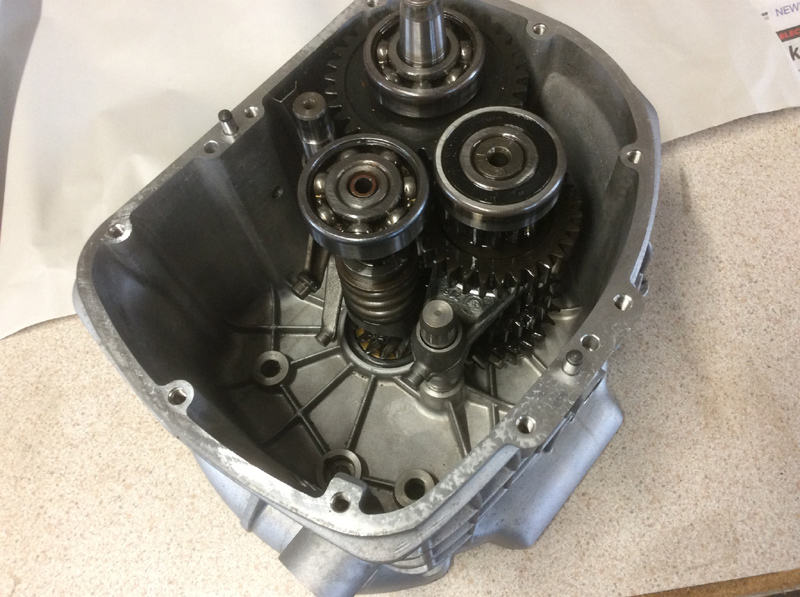

Once the gearbox was out and on the bench, it wasn't too difficult to dismantle it but first I made an extractor to remove the output shaft nut and flange. The nut is torqued to 180 lbs ft, so that needs a strong arm to remove it and the wave washer beneath. The flange is only held on a keyless taper and they can be TIGHT after the tightness of that nut! The inner end cover needs heating as the 3 large bearings it secures are an interference fit in it. It's a fairly straightforward box to strip and rebuild but cleanliness is essential of course.

Just the cam plate assembly to fit - the securing bolts for this are also an interference fit in the casing, so it needs heating again in that area so that they be fitted without binding. The cover gasket goes on next followed by the oil baffle plate on the intermediate shaft, then the original shims on all 3 shafts. The pre-heated cover then just slips in place over the bearings and dowels, then secured with the allen screws.

If you are doing a complete 'gears off shafts' strip and new bearings, then you will have to go through the rather tedious process of precision measurement and re-shimming to get pre-loads within spec - not necessary for me this time. Now that the casing is cool again, the seals can be fitted - I made drifts for these to avoid any damage and subsequent leaks. With a very thin application of Moly 60 paste (bought originally for the drive splines on the GoldWing) to the clutch driven plate and input shaft splines, the gearbox can now be refitted.